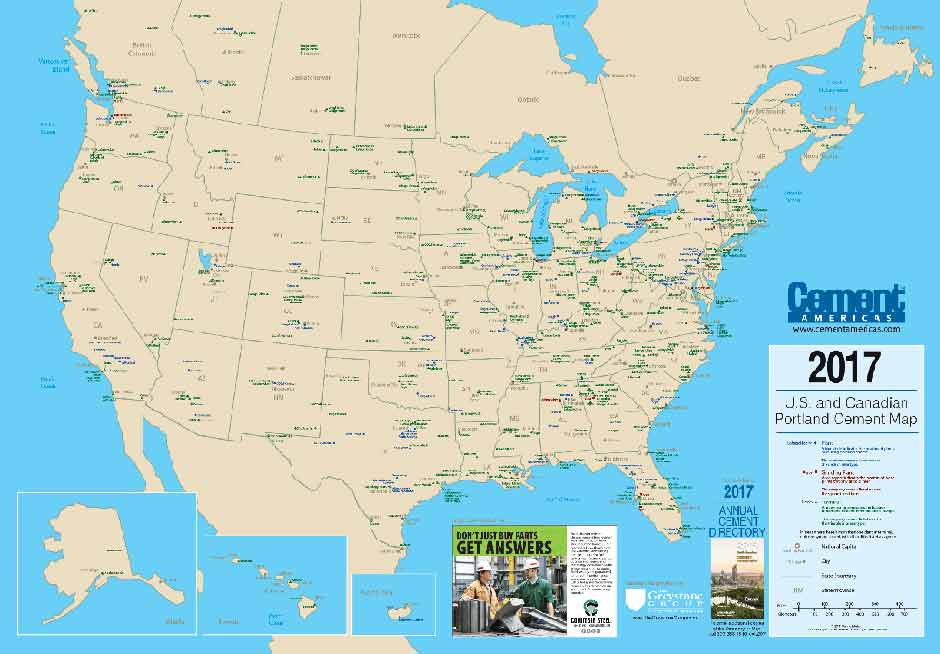

Available now for our cement industry clients: the 2017 U.S. & Canadian Portland Cement Map.

Showcasing over 500 facilities for clinker production, grinding, and distribution, this map is an invaluable resource for cement industry professionals. Published by Mining Media International and sponsored by Columbia Steel, the map retails for $70 — but it’s available free, while supplies last, for our customers and colleagues working in the cement industry.