Optimize Your Crusher Performance with a Customized Wear Study

In early June, Columbia Steel representatives will attend the 36th annual Elko Mining Expo in Elko, Nevada, alongside many of our industry colleagues. Events like this remind us of our connections to mining, which have served as a cornerstone of our business since our founding more than 120 years ago. Our roots supporting gold dredging operations in the early twentieth century eventually gave way to more sophisticated products that today power aggregate and surface mining operations worldwide.

As the mining industry continues advancing, we’re committed to developing new techniques and technology to help operators get the most from their equipment. Nowhere is this more important than in metallic mining environments where cone and gyratory crushers operate under sustained use. Fortunately, our customized wear studies are helping these operators get more life from their equipment without compromising production.

Customized Wear Studies Deliver Better Results

If you visit the Elko Mining Expo, you’ll likely hear us talk about the benefits of our customized wear studies. Customization is critical because the same liners will wear differently depending on location and the material being mined. Original equipment manufacturers (OEM) typically only offer a limited set of wear part designs based on what they deem to be average conditions. Columbia Steel takes a different approach.

When our engineers visit a site, they will evaluate equipment to discover high wear areas, estimate remaining service life and provide full surface wear measurements. In addition, our district managers can hand-profile used liners and then provide dimensional information to engineering, who will recreate the liner profiles. The district managers will also gather feed and discharge information, throughput rates, change-out records and gradation requirements.

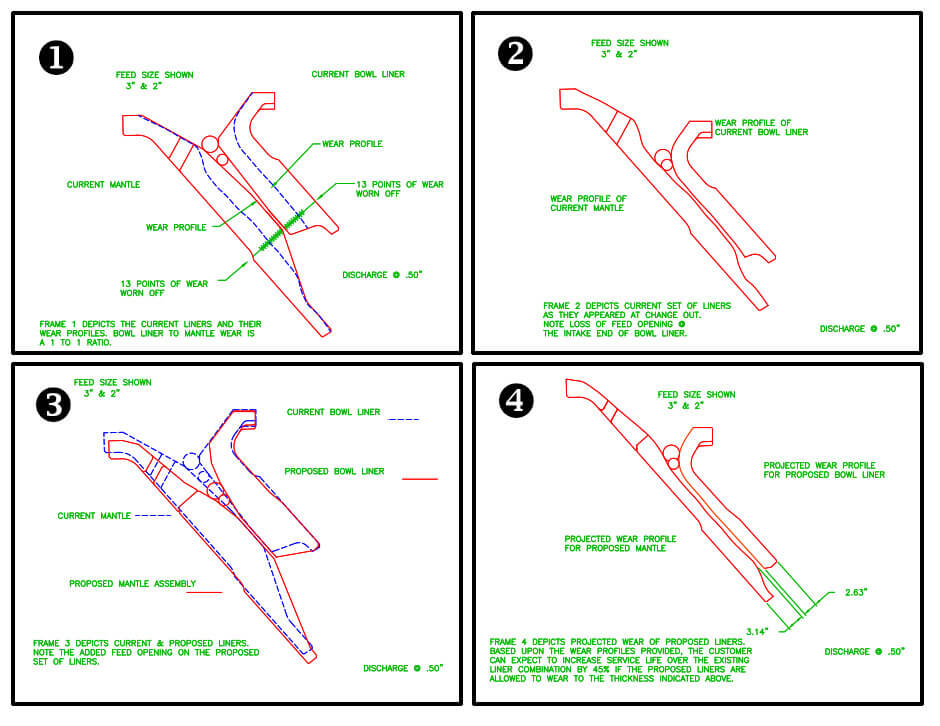

For cone crusher evaluations, our engineers compile a multi-part wear study to illustrate existing wear patterns and recommend changes that will improve part life and productivity. See the example below:

The first frame depicts the current parts as new, and then with the wear profiles. Our engineers use this information to determine wear rates between the two liners and how to balance parts, based on those rates. The second frame shows the worn profiles as they appear before change-out, providing insight into wear characteristics and how they may need to alter the liners. The third frame compares differences between the existing and the proposed liners. And, finally, the last frame projects the wear profiles of the proposed liners along with a calculated increase in service life.

By using customized solutions instead of a one-size-fits-all approach, our customers gain improved production, product sizing, better wear metal utilization, lower discard weight, longer wear-part life, and lower overall costs.

Improved Wear Parts for Improved Performance

Wear studies are only one of the ways we help metallic miners. Over the years, we’ve developed replacement parts for the most common crushing equipment, enabling our customers to get more life from their machinery and more value from the products they produce.

Cone Crusher Wear Parts

Through extensive research, development efforts and consultation with customers, Columbia Steel has created an extensive line of replacement cone crusher parts that outperform OEM alternatives. Our premium manganese steel products offer significantly longer life for mantles and bowl liners, while reducing downtime and change-out expenses.

Gyratory Crusher Wear Parts

As Columbia Steel developed its line of replacement gyratory crusher wear parts, our engineers went into the field and studied areas for potential improvement. These included poor nip of feed materials, excessive wear in the lower crushing chamber, poor throughput from partially worn parts, excessive metal discard with throwaway weight, and uneven or localized wear. In response, we’ve developed our own line of gyratory mantles and concave sets that have proven to be more durable and perform better than OEM options.

Attending Elko? Come Say Hello

Whether partnering with Columbia Steel for a customized wear study or installing one of our replacement crusher parts, you’ll have a team on your side that delivers custom-designed parts made from high-quality alloys manufactured in a facility that fully stands behind the products it makes. That’s an example of the comprehensive service we’ve provided the mining industry for more than a century.

Stop by our booth #513, if you’re attending the Elko Mining Expo on June 9 or 10. We’d love to say hello. If you’d like to learn more about our crusher replacement parts, wear services and customized solutions, you can also call us at (800) 547-9471 or fill out the contact form on our website.