WHITE PAPER

Induction Furnace Cooling Systems: One Foundry’s Experiences

— By David Havel, P.E., Columbia Steel Casting Co., Inc.

Presented to the Steel Founders’ Society of America National Technical & Operating (T&O) Conference, September 2016

Abstract

Induction furnaces come in all sizes and are very versatile tools for foundries. All types of metals can be quickly melted in induction furnaces. In addition, these furnaces offer the ability to switch between alloys with minimal alloy cross-contamination. All of these features make induction furnaces very popular in foundries. The cooling systems are a critical part of the furnace and are often overlooked until problems arise. When the cooling system is out of control, damage can begin to occur to the cooling system and the components it protects. Past experiences at Columbia Steel Casting Co., Inc. (CSCC) have demonstrated many of the issues that can occur. Sharing these experiences with other companies having similar problems illustrated the need for this paper. This paper will give a generalized description of modern induction furnace cooling systems and identify some of the important factors to control in maintaining these systems.

Introduction

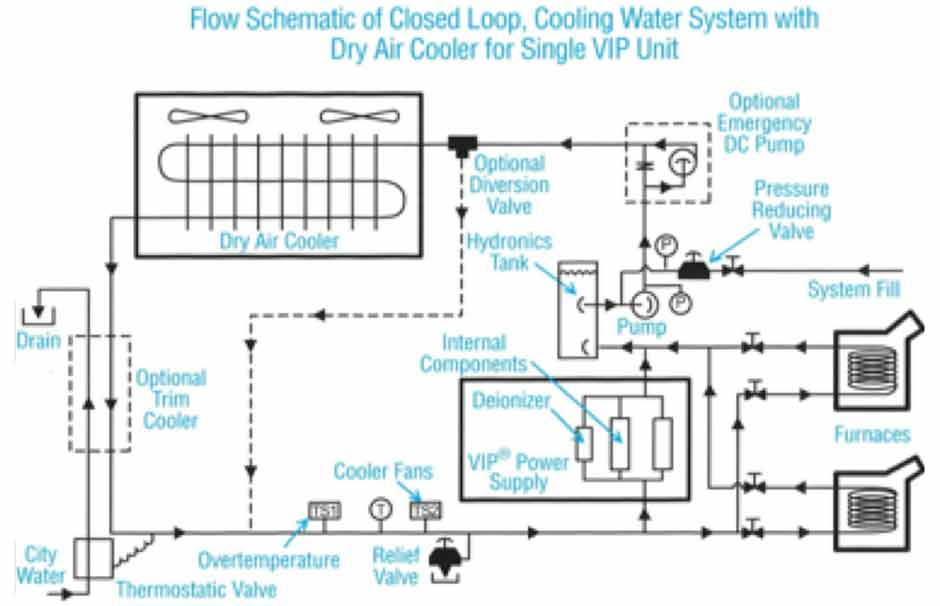

Induction furnaces are comprised of three main components. These components are the power supply (Fig. 1), the furnace bowl (Fig. 2) and the cooling system. The main components of a modern closed loop induction dry air cooling system (Fig. 3) consist of the pump module, dry air cooler, water path through the power supply, water path through the furnace bowls, deionizer filter, back-up system and optional trim cooler.

Fig. 1 Induction Power Supply:

Fig. 2 Induction Furnace Bowl System Components:

Fig. 3 Piping Schematic, Courtesy of Inductotherm:

These components and other smaller switches and valves make up a typical closed system with a dry air cooler. There is also the cooling fluid that flows through all of these devices. A closed loop dry air cooler system is now the standard for most induction furnace manufacturers.

However, other systems that use evaporative coolers or separate coolers for the power supply and furnaces do exist. Management of these systems, their cooling fluids, and its requirements are different. These systems will not be addressed in this paper.

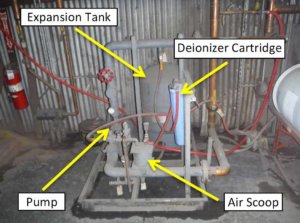

The pumping module (Fig. 4) can come in many configurations and may be mounted integrally to the power supply or may be a completely separate unit. Regardless of the unit’s configuration, its function is the same. This system provides the driving force to move the cooling fluid through the various components of the cooling system. The main component is the pump itself. Sometimes a backup pump is included in this system to prevent downtime if the main pump fails. An expansion tank will be present somewhere in the system and may be located within the pumping module. Valves to bleed air from the system will be located at or near the pumping system, as well as various other high points of the cooling system’s piping. These valves can be of the manual or automatic acting type.

Dry air coolers (Fig. 5) are sized not only by the required heat load, but also by the atmospheric conditions at the installation site. This type of cooler consists of fans that move ambient air through water to air heat exchangers. It is very important that these units are sized properly. In order to control the cost of these units, they may be sized so that there could be a few days each year when the ambient air temperature is too high and the unit cannot keep up with the cooling demand. In these cases, the use of a trim cooler can be beneficial. Benefits of a closed system include no ongoing water usage and minimal corrosion, scaling, or electrolysis. These factors help to keep the cooling fluid free of contamination.

Fig. 5 Dry Air Cooler:

The water paths through both the power supply and the furnace are critical. Inside the power supply the cooling fluid is routed through various components to keep them cooled. Many electrical devices are negatively affected by heat; this affect might diminish lifespan or even cause immediate failure. The water path through the furnace coil is removing all the heat that has transferred through the furnace lining from the molten metal to the coil area. Failure to remove this heat will cause damage to the furnace lining and coil.

A deionizer filter is typical on most units. This filter helps to keep the cooling fluid’s conductivity low. This filter must be periodically changed. A typical change out interval would be 2000 hours of operation or when the conductivity of the cooling fluid reaches 20 to 40 micromhos/cm.

The back-up cooling system is a critical component of the cooling system that is often overlooked. This system provides water circulation to the furnace coil in the event of a power failure. It is critical that cooling is available to the furnace in the event of power failure. These systems can be battery powered, engine powered, powered by a back-up generator or be switched to use city water. Periodic testing of these systems should be performed to ensure that this system will work when needed.

A trim cooler can be used to address undersized dry air coolers or to limit the size of a dry air cooler. These units consist of a water-to-water heat exchanger and are installed after the dry air cooler. When extra cooling is needed the city water supply is turned on and used to further drop the temperature of the cooling system fluid. The city water flow is typically sent to a sewer drain after the trim cooler.

The cooling fluid is the final component of the cooling system. This fluid must be very pure and have a low conductivity. Most manufacturers recommend the fluids conductivity to be less than 10 micromhos/cm. Water makes up around 60% of the fluid. This water should be deionized or distilled.

The remaining 40% of the fluid is glycol to prevent the systems from freezing during cold weather. Ethylene glycol is most commonly used for this purpose. It is important not to use anti-freeze made for vehicles because the various additives give these products a high conductivity. Ethylene glycol is toxic and therefore, some choose to use the non-toxic alternative, propylene glycol. If propylene glycol is to be used the size of the system must be increased by approximately 20% to allow for its lower heat capacity. These fluids can be purchased specifically formulated for this purpose.

System Design Basics

The furnace manufacturer will do most of the design work related to the cooling system. A few items are good to remember, however. When using deionized water the piping must be made from stainless steel or copper. Other metal piping options will be attacked by the water, and this leads to several problems. The furnaces themselves do not require deionized water, but the power supply does. In this paper, systems with single cooling units are the only ones being addressed so the furnace and power supplies discussed here will have the same cooling fluid. In the power supply low conductivity water is critical to prevent electrolysis within the system. If the conductivity of the cooling fluid gets too high some components will begin to dissolve and the dissolved material will later be deposited in other areas.

This leads to two problems. The components that have partially dissolved will eventually start to leak and break apart. In areas where this material has been deposited the fluid flow will be restricted or completely closed off. This will cause the effected components to overheat and eventually fail.

The circuitry in the power supply is also very sensitive to any electrical path between components that should be electrically isolated. Dissolved material inside the cooling hoses can create connections between components that lead to system shutdowns or component failures.

Due to the possibility of a connection through the cooling hoses, special non-conductive hose must be used. When replacing hoses the length of each hose must be kept the same. In many cases a shorter hose length would be physically possible but the desired isolation level of each component would be sacrificed. Cooling system hoses are typically designed to have a fifteen-year life. If conventional hose clamps are used to secure the hoses it is important that the entire clamp be stainless steel. If improper materials are present they may heat while the unit is operating.

Air bleeders should also be installed in the piping system at all high points. Automatic bleeders are preferred but the manual ones work just fine. It is better to install a few extra bleeder valves than not enough. The location of the dry air cooler should also be considered. External free air-flow paths are required around the cooler. Stray materials, like sand, must be kept away from the cooler to prevent plugging the internal air flow paths.

Afternoon sun exposure should also be considered when placing the unit. If possible, the cooler should be located so that during the hottest part of the day the sun is not directly shining on the unit.

Specific CSCC Operation Experiences

CSCC has operated induction furnaces for many years and during this time we have experienced many issues with this equipment. These events have been challenging, but in the end we are much better suited to handle issues in the future. Now we spend more time trying to prevent future problems versus reacting to the breakdown.

Prior to upgrading the power supply, our smaller furnace always had issues with conductivity in the cooling hoses. This lead to a standard practice where hoses were often changed, the dates were actually written on each hose so its age could be easily identified. This constant changing often required new hose clamps. We always buy stainless steel clamps, but found the fastener might not be stainless. We now buy marine grade hose clamps to ensure all components of the hose clamp are made from stainless.

We have also found that during really hot weather our larger induction furnace’s cooler cannot keep up and the unit will overheat. A mist of water placed under the cooler on these hot days brings the temperature down and allows production to continue. This practice can have some consequences if continually done, but it does work. Some OEMs now sell a dry air cooler with a built in misting system. It is important that clean filtered water be used to minimize any build up on the coolers fins.

One of the biggest issues was related to water conductivity. A conductivity meter is a great tool and can really help to identify problems. High conductivity is easy to overlook and many times the symptoms do not show up until much later. The first clue was when the newest power supply, which included a new cooling system, started to have manifold and fitting failures due to corrosion (Fig. 6).

At the same time, the older system started to have certain components overheat. In both cases, the cause of the problems was the same. The conductivity of the cooling fluid in both units was well over 200 micromhos/cm. It had taken awhile to discover this problem for a few reasons.

The first reason was the conductivity meter setting. The meter we use to measure the fluid has two ranges, and it was accidentally placed on the less sensitive range. So it was only reading 20-30 versus the actual 200 to 300 micromhos/cm.

The second reason was that the water system and its requirements were not fully understood at the time. Once this information was obtained, it became easier to understand what was happening. The high fluid conductivity was allowing electrolysis to occur. This new information helped to explain why some components were corroding away and others where plugging up.

The first action item was to repair the corroded fittings and clean the clogged cooling paths. In some cases, this required a chemical flush to remove the build-up. After the flushing chemical is used to clean to the piping it must be neutralized. Next the entire systems were flushed with city water and then ran on city water for a week. A second flush followed with another week running on city water. In our case, the city water supply is fairly clean with a low conductivity of less than 40 micromhos/cm. Due to its low conductivity this water can be used without any treatment for short periods of time.

In the meantime, the source of the high conductivity was sought and found to be the coolant itself. This fluid was being custom made by a local chemical company. The product they had been supplying was found to have a conductivity well over 200 micromhos/cm when it was brand new in the drum. After many conversations, a new product was formulated that has a conductivity less than 20 micromhos/cm. Both systems are now filled with this product.

Conclusion

Induction furnaces are widely used for melting metal in many foundries. They are very versatile and can provide many years of service if well maintained. The cooling systems are often overlooked and when all is running well, they are of no concern. This oversight can lead to unexpected downtime and costly repairs. Properly maintaining the cooling system will prolong the life of the furnace, lower maintenance costs, and reduce downtime.

Acknowledgements

Figure 3 is courtesy of Inductotherm, 10 Indel Avenue, P.O. Box 157, Rancocas, NJ 08073

The author is grateful for the contributions of Petr Brunetzky of Inductotherm, Pico Rivera, CA