Secrets to a longer life

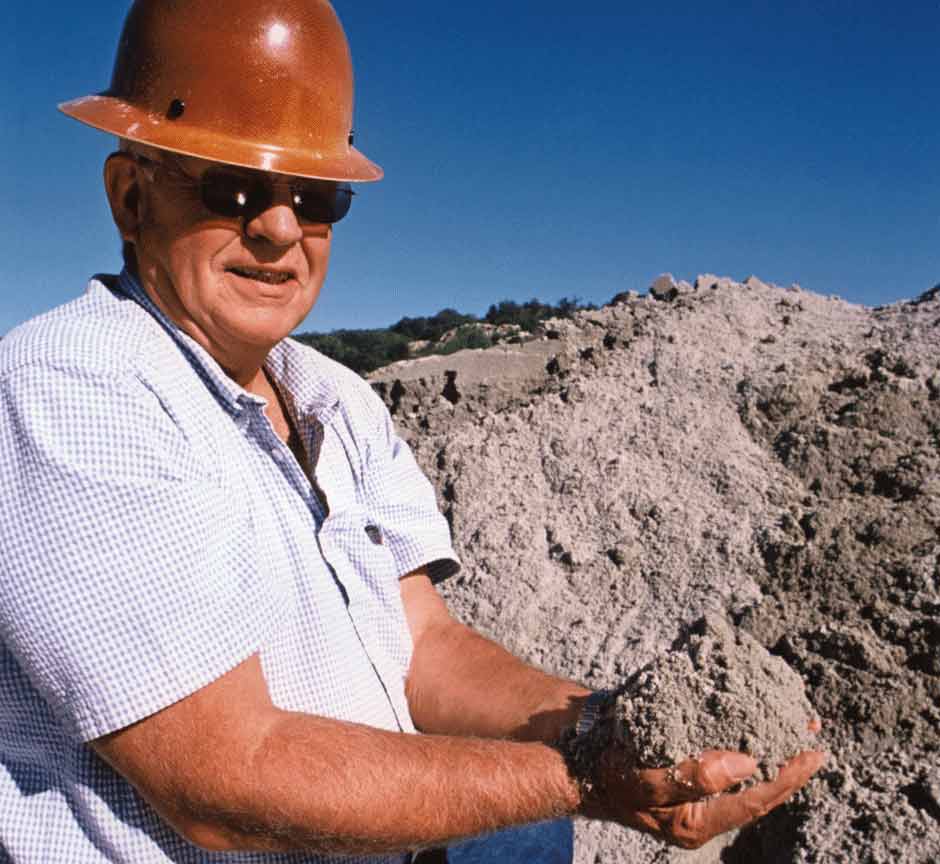

A manufactured sand producer in Tennessee finds that using the right jaw-crusher wear parts saves time and money in the long run.

— By Rodney E. Garrett

Highland Sand Co. in Crab Orchard, Tenn., produces manufactured sand at its quarry operation. The site produces only manufactured sand, with screened out fines sold as masonry sand.

Typical quarries necessitate multiples of crushers and screens with primary, secondary, tertiary and sometimes even quaternary plants in place for producing a list of aggregates products.

At the Highland Sand quarry, the complete plant is designed for producing the one product and while the production part is straightforward compared with multi-aggregates production, the company has had its challenges concerning the cost for wear parts. The high cost was not so much associated with the purchase price of the wear parts but the total usage cost owing to their short lifespan.

The concern of increasing crusher wear parts life is on the minds of most managers that are involved with manufacturing sand. While the physical attributes of sand make it ideal for using as aggregates in ready-mix concrete and asphalt paving products, sand is very abrasive and relatively hard. It is thus prudent for the sand manufacturer to investigate all possible avenues for increasing wear-parts life on its crushing and screening equipment.

Investigating is just what the Highland Sand Co. did and with results that more than paid for the effort in seeking better wear parts. Its success circles around the wear parts changes made to two of its jaw crushers. Here is some background on the company and its operation that led to solving the wear parts cost problems.

All in the family

The company was established in 1972 by brothers Jim and Arthur Rivers. Actually, their father bought the 140-acre tract at an earlier date with his intention to develop it into a quarry, but it never materialized. Prior to the quarry business, the brothers were operating a concrete masonry block and a ready-mix concrete company, so their knowledge of aggregates from a usage perspective in producing ready-mix concrete was already extensive. Most important, they knew what constitutes good-quality aggregates.

In order to hold capital costs low, Jim and Arthur decided to purchase used crushing and screening equipment and do most of the installation themselves. One of the company’s main equipment suppliers, Southern Machinery Co., Nashville, Tenn., designed the plant and gave them advice on how to put the plant together. Finally, the plant went online in 1974, processing 30,000 tons of sand that was sold the same year.

The rock quarried is sandstone with 94 percent silica (SiO2) content. Mining is carried out by drilling pre-designed blasthole patterns and blasting with specified explosives quantities to get rock fragmentation as close to 24-in. minus as possible. Most faces in the multi-bench quarry are about 50 ft. high. One shot yields about 25,000 to 30,000 tons of blasted rock. Highland Sand contracts the blasthole drilling, loading of explosives and blasting. Jim Rivers, now the sole owner of the company, says at one time the company did its own blasting, but with the new stringent government rules involved in handling explosives, they opted to use the services of a contractor.

What I like about Columbia Steel is they keep trying things to find out what works best. That is why our jaw crushers’ wear parts are so much better today.Today, the blasted rock at the face is loaded onto a 35-ton capacity Caterpillar off-road hauler using a John Deere front-end loader. The blasted rock is hauled to the primary jaw crusher, which is a Pioneer 24×36. All rock is dumped into a grizzly where the rock pieces 24-in. minus are scalped from the fines that would have a tendency to cause an extreme abrasive/binding action on the jaw crusher’s wear parts, according to Ronnie Snow, plant superintendent Rivers says the Pioneer crusher is an outstanding performer as is a Pioneer 15×36 jaw crusher that also is in use. “I have found these Pioneer jaw crushers to be very reliable. I also have two Pioneer VSI crushers in operation and they too are very good performers,” Rivers said.

The basic plant-production flow starts with the primary jaw crusher and then onto a Metso 5×14 double-deck screen where the top deck takes off 1/2 in. to 3-in. crushed rock and sends it to the secondary jaw crusher for further reduction to 1/2-in. minus. The 1/2-in. minus screened from the bottom deck is directed to a Pioneer 92-in. VSI crusher to make 100 mesh to 1/4-in. final product.

The crushed rock coming from the secondary jaw crusher is screened and sent to a 66-in. VSI for also producing sand with the same specifications. The sand produced by Highland Sand meets all Tennessee Department of Transportation specifications for aggregates used in hot mix asphalt and concrete paving mixes.

With this basic plant setup, the 15×36 jaw crusher’s stationary and moving jaw parts were flipped as early as every 30 days and then changed out for new ones every 60 days with the throughput production ranging between 20,000 to 25,000 tons per month. The rate of changing out the crusher parts had to do with the quantity of rock crushed for the month.

When changing or flipping the jaw parts, it took three men, four hours on the stationary jaw and two hours on the moving jaw. The 24×36 primary jaw crusher went through at least four sets of stationary and moving jaws per year. However, Snow said when crushing production was up, they had to replace a set after 60 days of use.

The financial bottom line to all of the wear parts changing was a very expensive practice for Highland Sand. Rivers decided something had to be done about the poor wear-parts-life performance shown with both jaw crushers. To that end, he called in the Columbia Steel people to see if they could design better performing wear parts.

Good engineering

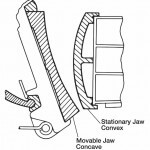

The Columbia Steel engineers got to work on improving the design of the wear parts and the possibility of changing the metallurgy to substantially improve the life of the parts. Rivers cooperated in every way with Columbia Steel for he had a stake in improving the costly wear parts phenomena as quickly as possible. The Columbia Steel engineers finally decided on a concave-convex jaw design.

Concave-convex jaws were designed for both jaw crushers. For the 15×36-jaw crusher, the jaws are manufactured using standard manganese with excellent results. Wear life enables the movable concave jaw to be used two years, according to Snow’s projections. Accordingly, the stationary convex jaw has a wear life of 18 months.The cheek plates are made with standard manganese steel and overlaid with Columbia Steel’s Xtend Process® for making them a bimetal part. Essentially, the design is intended to be the best of two types of steel by making the casting exceptionally tough and the bonded outer layer a very hard carbide steel that is highly abrasion resistant.

The Xtend bimetal concept has worked unusually well in different applications. However, with the exceptional extended wear life experienced with the jaw parts at Highland Sand, the Columbia Steel engineers are exploring the possibility of suggesting something else with even greater life expectancy under the crushing conditions experienced here. The goal is to design cheek pieces that will correspond to the longevity of the jaw parts.

Trial and error

The 24×36 jaw parts also are built with standard manganese castings and, here to, the life has been significantly increased to an average of one year per pair. Columbia recently sent K58 alloy cheek pieces for this jaw crusher to see if they will improve parts life to match the jaw parts longevity. “What I like about Columbia Steel is they keep trying things to find out what works best. That is why our jaw crushers’ wear parts are so much better today,” Rivers said.

To put this wear-parts improvement program into perspective, here is the math. These calculations are based on last year’s production of 250,000 tons of crushed rock: The 24×36 jaw crusher parts cost the company nearly $2,100 more than standard-design jaw parts would cost today. Standard-design jaw parts would cost about $7,000 today. Last year, the concave-convex jaw parts cost $0.03 per ton of rock crushed. Using standard jaw parts instead of the concave-convex jaw parts, the wear parts would have cost $7,000 times six changes or $42,000. Crushing the same 250,000 tons of rock last year using standard jaws would have brought the cost per ton to $0.16.

The total savings for the year are $32,500. That is not all: Rivers projects the company will be producing an average of 30,000 tons per month next year and that would mean savings of $4,800 per month or $57,600 for the year.

The figures do not include the labor savings required to make the additional jaw parts changes. Further, there has been a crushing throughput increase from 185 tph to 225 tph by using the concave-convex jaw parts.

Smaller jaw

Similar savings are enjoyed by Highland Sand using its 15×36 jaw. Both concave-convex parts cost about $1,800 more than standard parts would cost today. The bottom line to crushing the same quantity as last year would be $3,794 for the year using the concave-convex jaw parts and $4,700 per set for the standard jaw parts times six changes or $28,200. The net savings for using the 15×36-jaw crusher last year is $24,406. Again, these savings do not include the extra labor to change the standard jaw parts.

While unit price for the new improved jaw parts is up as much as 40 percent, the cost per ton of rock crushed is down by 533 percent. What this has demonstrated to Highland Sand is that the purchase price for the jaw wear parts tells little about their true cost to use. What matters is not the unit price of the wear parts but the unit cost per ton of rock processed through the given crusher.