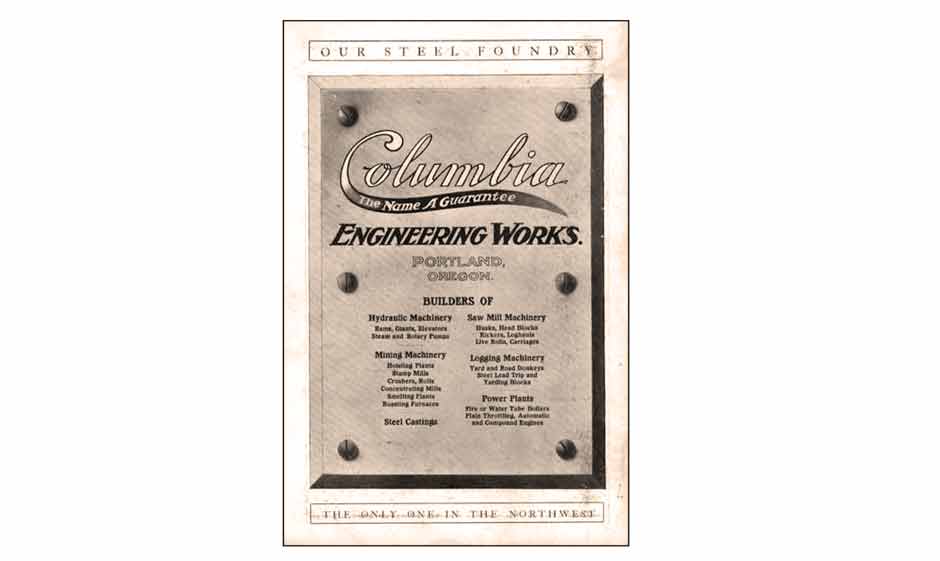

We began as an American family business in 1901 in Portland, Oregon.

The Northwest at the turn of the century

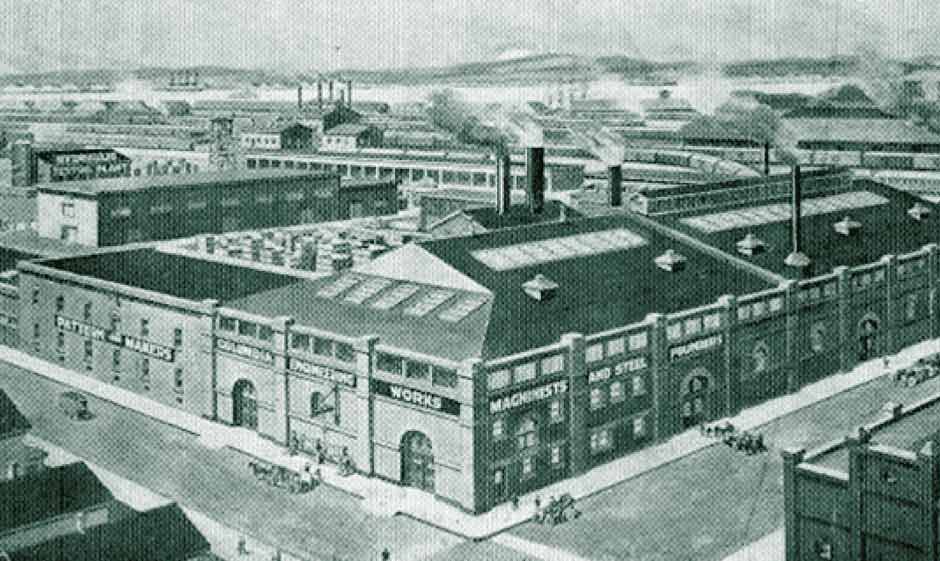

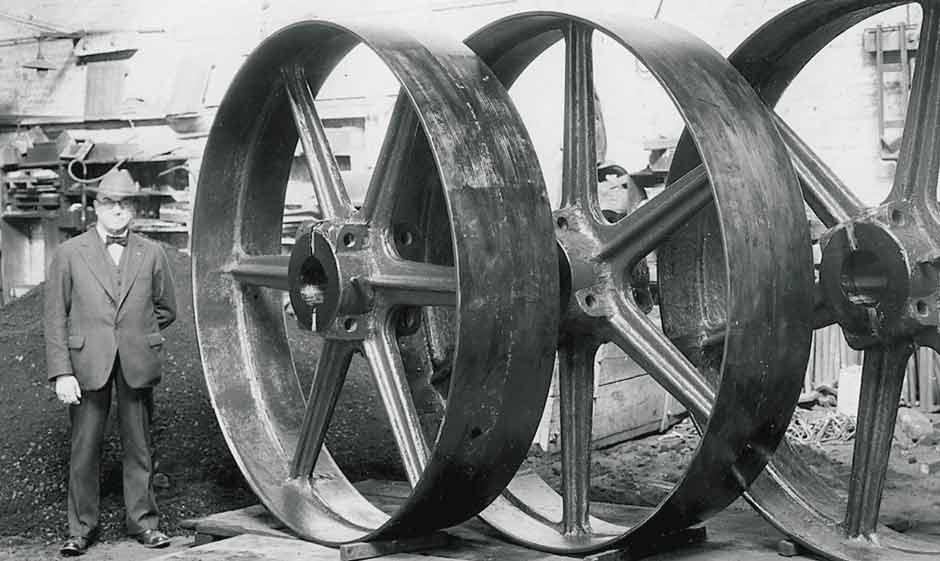

In 1901, Portland’s natural port via the Columbia River made the city a hub of commerce for inland industries like logging, mining and agriculture. The demand for cast steel products spurred immediate growth for Columbia Steel, the first steel foundry in the Northwest. Products of the time included railroad track switches and crossing frogs; parts for ships, such as stern frames, rudders and anchors; and parts for gold dredges.

Years of World War I

The horseless carriage was beginning to catch on, creating a need for better roads — and a growing demand for crushed aggregate. Columbia Steel manufactured parts for stamp mills and Blake-type jaw crushers, and later Gates gyratory breakers and overhead eccentric jaw crushers. The development of the steam shovel allowed loading of larger feed material, and by 1910, gyratory crusher feed sizes had grown from 18” to 48”.

The Roaring ’20s

In 1923 the first three-phase electric arc steel melting furnace west of the Mississippi River was installed at Columbia Steel. In those days, Columbia made manganese steel by the “duplexing” method of melting ferromanganese in a cupola and mixing it in a ladle with steel from the arc furnace.

Surviving the Great Depression

The Wall Street crash of 1929 seriously impacted many of the manufacturers who relied on Columbia Steel castings. Fortunately, the company had established a strong reputation in the gold dredging industry, and this market made up about eighty percent of Columbia’s business, ensuring its survival during the ‘30s.

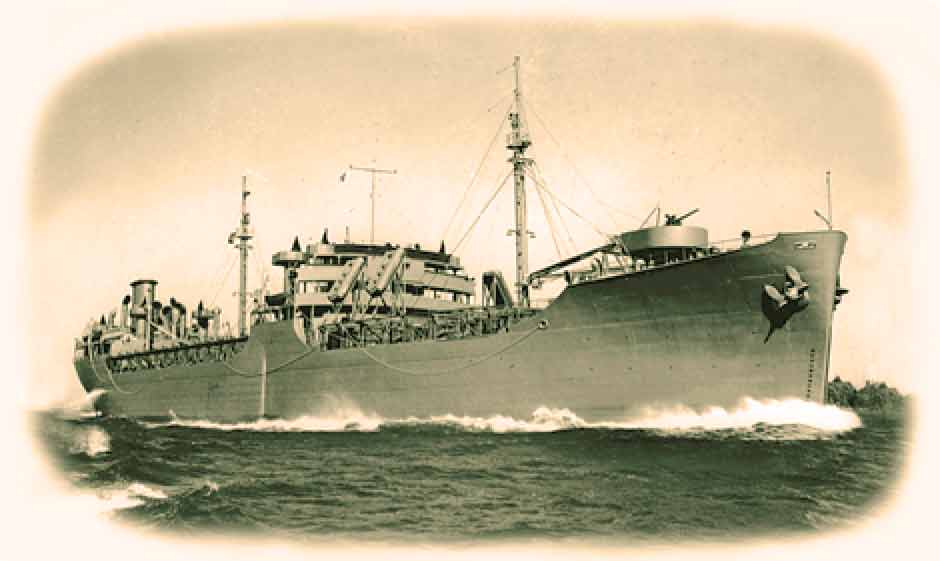

Wartime castings in the ’40s

Immediately after the country’s entry into World War II, a major ship building industry was rapidly established along the banks of the Willamette and Columbia Rivers. Columbia Steel’s foundry had a remarkable capacity for the times, making it a principal source of large steel castings for the US Navy. Columbia’s performance in this production effort was acknowledged by the award of the Navy “E” flag for excellence in achievement.

New directions

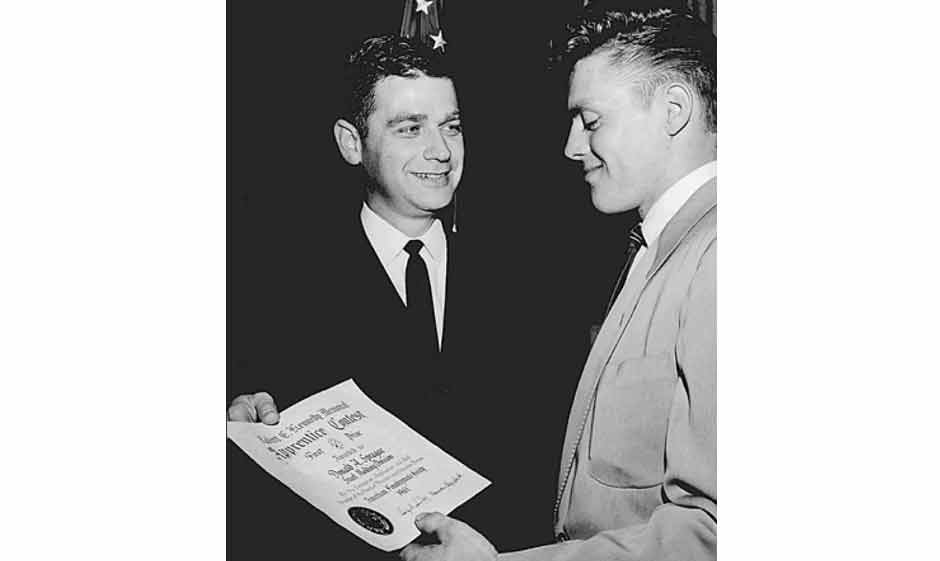

During the late ’40s and early ’50s, new copper mines were being opened in the Southwest, and this was good news for Columbia, thanks to its ability to produce replacement parts for metallic mining equipment. The 1960s were devoted to upgrading facilities to produce larger parts, thicker sections, complex configurations, tighter tolerances, and new alloys. During the ‘70s, Columbia began pouring high strength martensitic steels. In 1986, the company introduced a premium manganese steel, trade named Xtralloy®, which proved highly successful in aggregate and mining crushers. By 1990, Columbia Steel was one of the larger domestic manufacturers of replacement wear parts for industry.

Today’s Columbia Steel

In January 2023, Columbia Steel Casting Co., Inc. reached an agreement with the CMS Cepcor Group for the sale of key commercial and technical assets. The agreement will see the CMS Cepcor Group incorporate a new company “Columbia Steel Cast Products LLC”, which will trade independently as “Columbia Steel” and retain the key Columbia Steel engineering, sales, and commercial team. The CMS Cepcor Group is excited to further expand its global footprint, as well as grow the respected reputation Columbia Steel has held in the aggregate and mining marketplace for decades.